Our involvement with the idea of using very low pressures to control stored-product insects, dates from the 1960's and even then, it was initiated by our belief that non-chemical control measures would eventually be needed to replace the chemical ones that were widely practiced at the time. "Vacuum" fumigation was then a well-known technique used to enhance fumigant penetration into products and reduce exposure time, but vacuum had not been seriously considered alone. Our findings showed that very low pressures were required to obtain insect kill in reasonable time periods, and that there was a close correlation between the partial pressure of the remaining oxygen and the rate of kill under hypoxia. This led us to hypothesize that hypoxia and not the vacuum itself is responsible for mortality. However, to obtain 0% to 0.5% oxygen, a pressure of 25-50 mm Hg is required, and even at these low oxygen concentrations several hours are required to produce complete kill. Since this treatment could only be carried out in specially constructed vacuum chambers, the practical oucome of this research could not be realised at the time.

Only in the 1980s were we given the opportunity to do a re-think on this near-forgotten technology. The desperate search for alternatives to the use of Methyl bromide prompted us to present a two-year research proposal to the US-Israel Scientific and Technology Foundation (USISTF). This proposal was funded, was completed, and a second follow-up research project was carried out. Originally we intended (together with our partners at Oklahoma State University) to develop the GrainPro Cocoon, as a turn-key technology for combining modified atmospheres and elevated temperatures to obtain rapid kill of insect pests. (ICM=Integrated Commodity Management). However, one of the spin-offs of this joint project was that Philippe Villers of GrainPro suggested that we re-examine the possibility of vacuum treatments inside the flexible plastic liners. The second project focussed therefore on the use of low pressures alone or in combination with high temperatures (ambient temperatures of up to 40C) and/or high carbon dioxide concentrations for the rapid control of insect pests of both durable and fresh agricultural producs as well as the use of prolonged low pressures in flexible storage liners for quality control of high value durable crops such as spices.

|

|

Together with our cooperating partners we have undertaken and are continuing to undertake both laboratory studies and a number of commercial size storage trials both in Israel (Bet Dagan and Holon), the US (Boston) and the Ivory Coast (Abidjan). Already, these have convincingly shown that through development of an effective evacuating system, very low pressures can be obtained and maintained within the standard GrainPro Cocoons for indefinite periods of time. This technology has been patent-applied-for, and although much has still to be done to apply and characterize the process for the large number of commodities to which it may be applicable, we are confident that a wide field of applications both for insect control and quality maintenance lies before us.

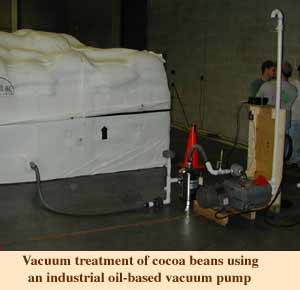

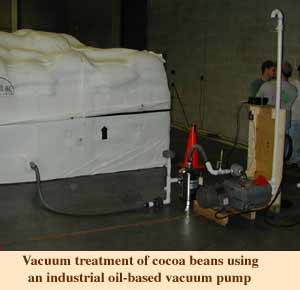

The first two pictures show the set-up during our initial trials on stored cocoa beans in Boston, Massachusetts. Here a Becker oil pump was used with two filters. Bioasseys of insects placed within the cube indicated succesful control at short exposure periods, but the range of low pressures under practical conditions and the durability of the pump under heavy-duty usage had to be further investigated. We found that water vapour released from the cocoa beans condensed and contaminated the oil of the pump during prolonged use to a point where the pump was no longer effective.

The following two pictures show the set-up of our first vacuum trials held outside our laboratory in Israel. Here we also used cocoa beans, this commodity being of special interest due to the necessity of fumigating all cocoa beans exported from the tropical countries of cultivation. Such fumigations have been carried out until recently with methyl bromide since the slow action of phosphine is a great disadvantage during the handling procedure at the dock-side. These preliminary trials in Israel were undertaken to simulate the trial carried out later in the Ivory Coast. Two vacuum cubes (later shipped to the Ivory Coast) were loaded with cocoa beans which were part of a consignment of imported cocoa by one of Israel's largest chocolate manufacturers. The trial was designed for testing exposures of 3 and 7 days. During the operation of the pump oil samples were taken to determine oil

contamination. Also to demonstrate the feasibility of obtaining complete kill of all stages of insects within the targeted time spans and temperatures, caged insects of all stages of Tribolium castaneum and Ephestia cautella were introduced.

The right hand picture shows the snap-on quick release pressure hosing used to attach the cube to the pump. This was branched so that both cubes were served in parallel by the same pump.

|

|

The next two pictures (below) show the Becker oil vacuum pump (left) used in the first trials in Israel. The two carbon filters can be clearly seen as well as the control panel. The picture on the right shows the quick connections used to link the storage cube to the pump, and the inlet valve for carbon dioxide flushing used in trials where combined vacuum and high carbon dioxide were employed.

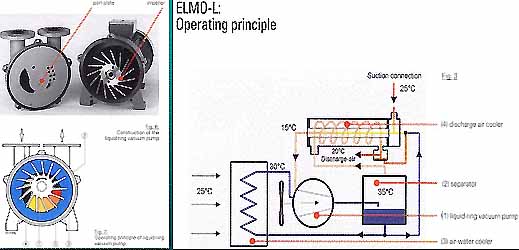

The Siemens liquid-ring pump of the Elmo F series was found to have insufficient performance

at ambient temperatures above 25°C. Therefore for the preliminary trials in Israel and those in the Ivory Coast, we reverted to the Becker Rotary Vane Vacuum Pumps working on oil.

Trials with the oil pump in Israel showed that for continuous operation of the pump a

two-stage set-up of charcoal packed air filters, and a water evaporation system to avoid

accumulation of condensed water was necessary to prevent contamination of the oil in the

pump. This system together with the use of mineral oil, allowed the pump to operate continuously for several weeks with an on-off pressure control system within the limits

of 23 and 75 mm Hg absolute pressure. A similar set-up was adopted in trials

carried out in the U.S.A. by our R&D partners, GrainPro.

|

|

The next series of pictures were taken during two trials carried out in collaboration with a leading fumigation company in Israel in a food factory for packaging of semolina for baby food. Semolina, has a bulk density which makes it difficult for fumigant penetration, thereby leaving pockets of low fumigant concentration. Neither can semolina be seived to remove insects since the particle size of semolina is similar to that of insect eggs.

Evacuation took place using both the Siemens liquid-ring pump of the Elmo F series and the Becker pump U.4.70 SA/K to obtain pressures within the range of 100 mm Hg and 75 mm Hg, with an exposure time of 120 hours.

Bioasseys using caged insects of all four development stages of Ephestia cautella and Oryzaephilus

surinamensis resulted in complete control.

The first two pictures (below) show the quick connection in these trials and pallets filled with polystyrene blocks used to prevent collapse of the pallets under vacuum.

|

|

The next two pictures (below) show the liquid ring/water pump and a diagram of the operating principle.

|

|

Lastly we see the stack after vacuum treatment,(top left) the control panel of the liquid ring pump (top right), a picture of Shlomo, Simcha and Ali, set-up of the second trial (bottom left), and a close up of the pressure monitor (bottom right).

|

|

|

|

Calderon, M., and Navarro, S. (1968). Sensitivity of three stored product insect species exposed to different low pressures. Nature 218: 190.

Calderon, M., Navarro, S. and Donahaye, E. (1966). The effect of low pressures on the mortality of six stored product insect species. J. stored Prod. Res. 2: 135-140.

Donahaye, E. and Navarro, S. (1988). Sensitivity of two dried fruit pests to methyl bromide alone, and in combination with carbon dioxide or under reduced pressure. Trop. Sci. 29: 9-14.

Navarro, S. (1974). Studies on the effect of alteration in pressure and composition of atmospheric gases on the Tropical Warehouse moth, Ephestia cautella (Walker), as a model for stored product insects. Thesis submitted to the Hebrew university of Jerusalem for the Degree "Doctor of Philosophy".

Navarro, S. and Calderon, M. (1972). Exposure of Ephestia cautella (Wlk.) (Lepidoptera, Phycitidae) to low pressures: effects on adults. J. stored Prod. Res. 8: 209-212.

Navarro, S. and Calderon ,M. (1979). Mode of action of low atmospheric pressures on E. cautella (Wlk.) pupae. Experientia 35: 620.

Navarro, S. and Donahaye, E. (1972). An apparatus for studying the effects of controlled low pressures and composition of atmospheric gases on insects. J. stored Prod. Res. 8: 209-212.

Navarro, S. and Donahaye, E. (1987). Sensitization of insects to fumigation techniques including reduced pressure. Proc. 4th Int. Wkg. Conf. Stored-Product Protection Tel Aviv, Israel Sept 1986, 345-351, Maor-Wallach Press, Jerusalem.

Navarro, S., Donahaye, E. Dias, R., Azrieli, A., Miriam Rindner,

Phillips, T., Noyes, R., Villers, P., deBruin, T., Truby, R. and Rodriguez, R. (2000). Application of vacuum in a transportable system for insect control. In: Donahaye, E.J., Navarro, S. and Leesch J.G. [Eds.] (2001) Proc. Int. Conf. Controlled Atmosphere and Fumigation in Stored Products, Fresno, CA. 29 Oct. - 3 Nov. 2000, Executive Printing Services, Clovis, CA, U.S.A. pp. 307-315

File size=428k

File size=428k

Navarro, S., Donahaye, E., Dias, R., Miriam Rindner and Azrieli, A. (2000). Insect control using vacuum or CO2 in transportable flexible liners. (accepted for publication in MBAO)

Finkelman, S., Navarro, S., Miriam Rindner, Dias, R. and Azrieli, A. (2002) Effect of low pressures on the survival of cacao beans insects stored at 18°C. Journal of stored Products Research (In press)

Finkelman S., Navarro S., Isikber A., Dias R., Azrieli A., Miriam Rindner, Lotan Y. and Debruin T. (2002) Insects control of cocoa pests using a novel vacuum approach. Proceedings of the 8th International Working Conference on Stored Product Protection, York, UK. (in preparation).

Finkelman S., Navarro S, Villers P., Lotan Y. and DeBruin T. (2002)

Vacuum- hermetic fumigation system for cocoa beans as alternative to fumigation with phosphine. Proceedings of the 8th International Working Conference on Stored Product Protection, York, UK. (in preparation).

Navarro S., Finkelman S., Sabio G., Isikber A., Dias R., Miriam Rindner, and Azrieli A. (2002). Enhanced effectiveness of vacuum or CO2 in combination with increased temperatures for control of storage insects.

Proceedings of the 8th International Working Conference on Stored Product Protection, York, UK. 2002 (in preparation).

Finkelman S., Navarro S., Isikber A., Dias R., Azrieli A., Miriam Rindner, Lotan Y. and Debruin T. (2002).

Application of vacuum to sealed flexible containers: a viable alternative to disinfestation of durable commodities with methyl bromide.

Proceeding of International Conference on Alternatives to Methyl Bromide (eds. T.A. Batchelor and J.M. Bolivar), pp. 130-133 Sevilla, Spain. European Commission, Brussels, Belgium.

S. Navarro, S. Finkelman, G. Sabio, A. Isikber, R. Dias, M. Rindner And A. Azrieli (2002). Quarantine treatment of storage insect pests under vacuum or CO2 in transportable systems.

Proceeding of International Conference on Alternatives to Methyl Bromide (eds. T.A. Batchelor and J.M. Bolivar), pp. 130-134 Sevilla, Spain. European Commission, Brussels, Belgium.

Navarro S., Finkelman S., Donahaye E., Dias R., Miriam Rindner and Azrieli A. (2001) Integrated storage pest control methods using vacuum or CO2 in transportable systems.

Meeting of the IOBC WPRS / OILB SROP working group integrated protection of stored products (eds. A. Cornel and S. Navarro), p. 31 Lisbon, Portugal.

Navarro S., Finkelman S., Donahaye E., Miriam Rindner, Dias R., Azrieli A. (2001) Laboratory and field tests on vacuum or CO2 for the control of storage insects.

Annual International Research Conference on Methyl Bromide Alternatives and Emissions Reductions (eds. G.L. Obenauf and R. Obenauf), p. 68-1. San Diego, CA, USA.