Technology of Forage and By-Products Preservation

3. The history of forage preservation by ensiling, and basic terminology

Hay making is probably the most ancient means of forage preservation. After cutting, the crop would be left on the ground for drying without any additional treatment except, possibly, for turning it to ensure uniform drying. Such a technology, which is simple, is practicable in hot areas where there are also dry seasons.

Fig. 1. Mural in ancient Egypt, 1500-2000 B.C.E. Ensiling wet forage.

Preservation by fermentation and utilization of microorganisms has been known since the beginning of civilization; pickles, wine and dairy products all rely on microorganism activity. The first evidence of ensiling forage comes from archaeological evidence in ancient Egypt, in a mural from the second millennium BCE Fig. 1 . In the book of the prophet Isaiah (700 BCE), chapter 30 it is also mentioned that silage was fed to animals. The Roman historian Cato (100 BCE) mentioned a German tribe - the Teutons - that used to preserve green forage in a pit, covered with dung. The modern era of silage making originated with a French farmer named Goffart who, in 1877, published a book describing his experience. He advised to "preserve corn in a barn in such a way as to exclude the air that causes deterioration". This book was translated into English and was distributed in England and the USA. In 1920 a Finnish researcher named A. I. Virtanen developed the system of adding mineral acids - mainly sulfuric acid - to improve fermentation. This system, known as the A.I.V. system, is still in use in some Scandinavian countries when it is necessary to ensile very wet material.

There is no doubt that five major factors have affected the development of ensiling technology in the last few decades; development that has gained this technology the most dominant status in forage preservation in modern agriculture. These factors are:

- Better understanding of the sciences of chemistry and microbiology.

- The discovery of the ensiling advantages of the "new crop", corn.

- Developments in agricultural mechanization.

- The appearance of plastic products.

- The development of additives.

However, in comparison with haymaking, preservation of forage by ensiling needs more equipment, skill and investment, therefore, this technology is still not popular in some developing countries.

The following are selected literature definitions regarding silage and ensiling:

- "Silage is the material produced by fermentation of a crop of high moisture content".

- "Ensiling is the name given to the process, and the container used is called a silo".

- "Silage is the preservation of forage crops in an acidic, oxygen-free environment".

- "The basic process of silage making is to change forage to silage, to change the pH from about 6.5 to under 4.0, and to convert sugars to acids, mainly lactic acid, by means of lactic acid bacteria" (LAB).

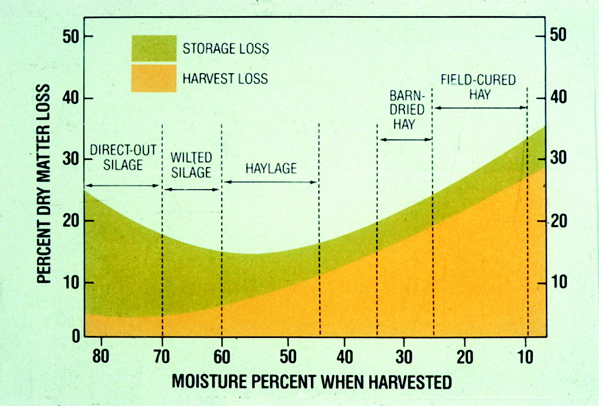

Fig. 2. Dry matter losses related to the preservation technology.

All these definitions are correct, and others could be added. It is important to remember that silage and ensiling relate not only to forage materials, but can also serve as a technology to preserve wet by-products. Comparison between the technologies of preservation of forage by drying (haymaking) or by ensiling shows that in haymaking most of the losses are harvest losses, mostly in the field, whereas in ensiling most of the losses are storage losses. Total losses are the combined total of harvest and storage losses Fig. 2.

There are three basic conditions to make ensiling possible:

- Enough fermentable sugars to support the bacterial activity.

- Suitable conditions for the desirable bacteria to be active.

- Appropriate composition and correct numbers of the desirable microorganisms in the raw material.

Which products can we preserve by ensiling? Actually, it is possible to preserve almost all biological materials by ensiling: forage crops, by-products, and residues. Of course, the quality of the end product (silage) will be affected by the quality of the raw material (forage or by-product), especially its intrinsic ensilability, by the additives used to improve fermentation, and by the quality of the prevailing husbandry.

How can we manipulate the raw material to achieve the highest potential quality?

- Acquire the raw material at the stage of highest quality and ensilability.

- Use the best technological means to ensure a good fermentation process.

- Enrich the raw material to improve fermentation.

- Prevent any avoidable losses.